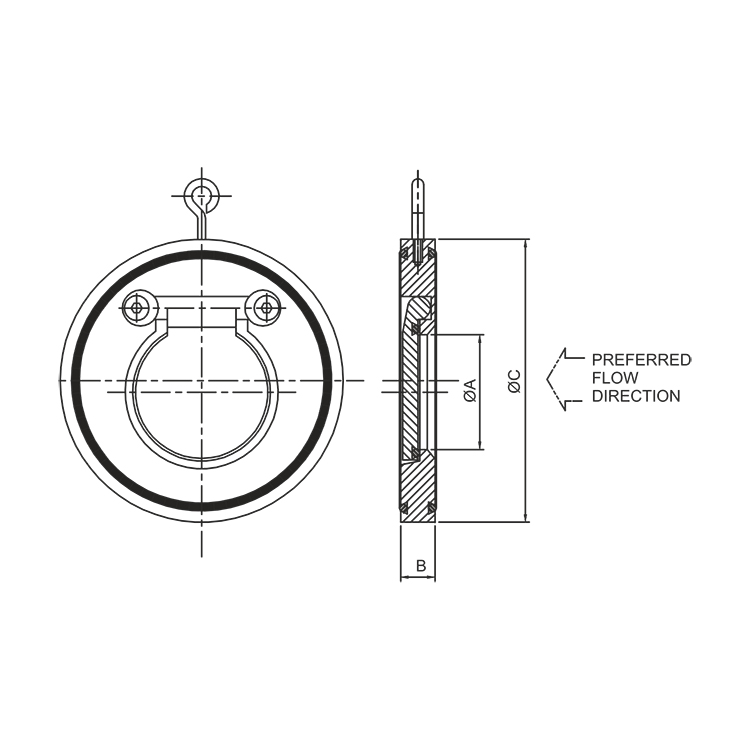

Wafer Check Valve

Conformity To Standard & Codes

| General Design & Face to Face Dimensions | ASME B 16.10 / API 6D |

|---|---|

| Valve Testing | B16.10 |

| Flange Standard | ASTM B 16.5 #150, DIN EN1092- PN10 & PN 16 BS 10 Table D & E |

Hydrostatic Test Pressure (kg / cm2)

| Rating | Body | Seat |

|---|---|---|

| Class 150 | 31 | 23 |

| PN 16 | 24 | 16 |

| PN 10 | 15 | 10 |

Technical Specification

Key Features

All Dimensions are in mm Unless Specified

| Valve Size | ∅A | B | ∅C | ||||

|---|---|---|---|---|---|---|---|

| PN10 | PN16 | BS10D | BS10E | ANSI#150 | |||

| 25 | 14 | 16 | 72 | 72 | 69 | 69 | 64 |

| 40 | 22 | 19 | 93 | 93 | 86 | 86 | 83 |

| 50 | 30 | 19 | 108 | 108 | 97 | 97 | 102 |

| 65 | 40 | 19 | 128 | 128 | 110 | 110 | 121 |

| 80 | 52 | 19 | 143 | 143 | 129 | 129 | 134 |

| 100 | 71 | 19 | 163 | 163 | 161 | 161 | 172 |

| 125 | 93 | 19 | 193 | 193 | 193 | 193 | 194 |

| 150 | 114 | 19 | 219 | 219 | 218 | 215 | 220 |

| 200 | 157 | 28.5 | 274 | 274 | 274 | 272 | 277 |

| 250 | 195 | 28.5 | 329 | 329 | 225 | 335 | 337 |

| 300 | 230 | 38 | 379 | 385 | 285 | 383 | 407 |

| 350 | 270 | 44.5 | 438 | 444 | 446 | 446 | 448 |

| 400 | 310 | 51 | 489 | 496 | 496 | 496 | 512 |

| 450 | 360 | 60 | 538 | 555 | 559 | 559 | 545 |

| 500 | 406 | 64 | 593 | 616 | 616 | 616 | 602 |

| 600 | 490 | 70 | 695 | 733 | 727 | 724 | 714 |